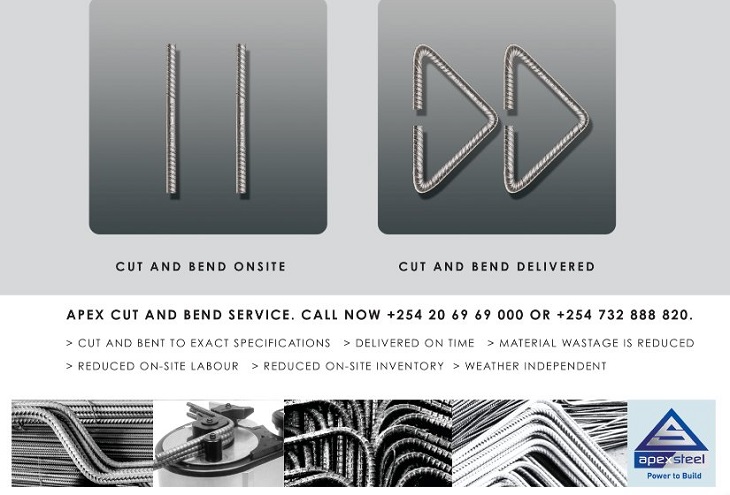

Ordinarily cut and bend is done by unskilled labourers. This consequently leads to inefficiencies such as the wastage of materials.

The bigger the project the more wastage there is thus the introduction of cut and bend off-site is revolutionary to the construction industry.

Benefits of Cut and Bend:

Easy and fast preparation of bill of quantity – Due to better estimation of reinforcement steel for the whole project, hence better accountability and audit of building materials.

Labour saving on-site – A project needs fewer people on-site to cut and bend the bars and look after the wastage or the bars that need to be re-used elsewhere.

Space Saving – The contractor will not need a cut-and-bend machine or a place to do it on site.

Relief from onsite congestion – There is no clutter of waste that would otherwise result from cutting on site.

Pilferage on-site – With cut-and-bend pieces coming ready, there will be no wastage on-site to pilfer.

Security – The lack of wastage on-site reduces the potential for theft.

Hassle-free construction – One can get just-in-time deliveries and there is no waste material, hence you don’t have to arrange for waste disposal.

Efficiency – It is simple, safe, and operational. APEX TMX rebars are customized to the project.